Building a Pelican (February 17th 2001, part 4)

|

February 17th 2001 Week 33 of our follow-up of the building of a Pelican Sport from Ultravia Aero International Inc. |

|

||||

| Luc and Jean-Claude Pasquet preparing small adjustment parts.

Last week (left) using high technology hand saw... and this week below. |

||||

|

||||

| Film ended, rewinded and camera in its carrying case, I'm ready to go home. Jean-Luc Arsenault asks me with a smile "Did they show you what they received this week?" ... "The variable-pitch propeller"

Didn't take long for another film being put in the camera... (no a bad idea since I finsihed the film the following day with pictures of a slightly larger bird than a Pelican...) And yes, there is now a new page in this web site on the Antonov An-124 "Condor" in the aircraft observation section . After all it is the second largest plane in the world and I don't think I will be lucky enough to see the largest one, the Antonov An-225 Mryia ("Cossack").

Let's get back to our variable-pitch propeller... |

|||

|

|

|||||

|

||||||

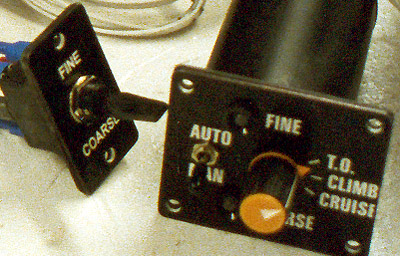

| Jean-Claude Pasquet holds one of the blades near the spinner (cone). Also shown are the control box, the switch and control mechanism (orange button) for the blades pitch. These will be installed in the instruments panel. | ||||||

|

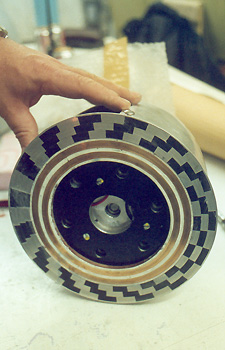

Without it's protective cone, we can see the spinner mechanism. | |||||

|

||||||

|

||||||

| Right, the the two copper circles are electrical contacts. The three concentric series of black lines permit a three position adjustment of the blades pitch. Inner circle for take off, mid circle for climb and external circle for cruise. | ||||||

| Made in New-Zealand the blades are from "Warp Drive". The spinner is an "Airmaster" | ||||||

|

Ajusting the pitch for propeller blades can be a delicate operation when they are fix-pitch type (That is it remains the same during flight). A compromise must be made between power for take off a efficiency at cruise speed. Normally, the propeller efficiency will drop dramatically over a certain air speed. That is why on planes meant to fly fast, a variable pitch propeller would be installed. | ||||

|

The Pelican is not exactly a plane built for high speed. Luc and Christian chose to install a variable-pitch propeller for maximum traction on take off since they plan to install floats on this plane in summer time. With a fixed-ptich prop they would have had to adjust the blades for maximum take off and climb efficiency and loosing efficiency for the cruise which remains the major part of flight time. In the animation above we can see the prop does not work the same way at low pitch for take off (upper trace) than at high or coarse pitch for maximum cruising speed (lower trace). In both animations, note that the propeller rotation speed is identical. Thus the engine rotation per minute (RPM) is constant. It is the blade pitch (or angle) taht varies. This is why the variable-pitch propeller is more often called the constant speed propeller. |

|||||

| If you want more information on constant speed propellers, I suggest you visit the following site for a text written for flight simulators "pilots". The text is intended for aircraft enthusiasts and explains the way this type of propeller works and its advantages.

pcme.com/Home/home.html?article=/articles/023/158/flighta_column.html |

|||||